Prestressed concrete is the type of concrete that has a tensioned steel inside the concrete as strands , the basic concept of this concrete is to transform the section from tension - compression section to compression -compression section .

This can be happened when the steel is tension until we reach a certain limit then we cut the steel so the force that will applied from steel to the section is compression force .

And we can reduce the stress by introducing moment from the steel by make a eccentricity from the centroid (M=P*e) and the stress will equal (stress=My/I )

The profile of the steel is called tendon and there are many shapes of it :

1- linear profile : we can called this type constant eccentricity .

2- parabolic profile : we can called this type variable eccentricity .

3- linear - parabolic profile

Method of prestressed concrete :

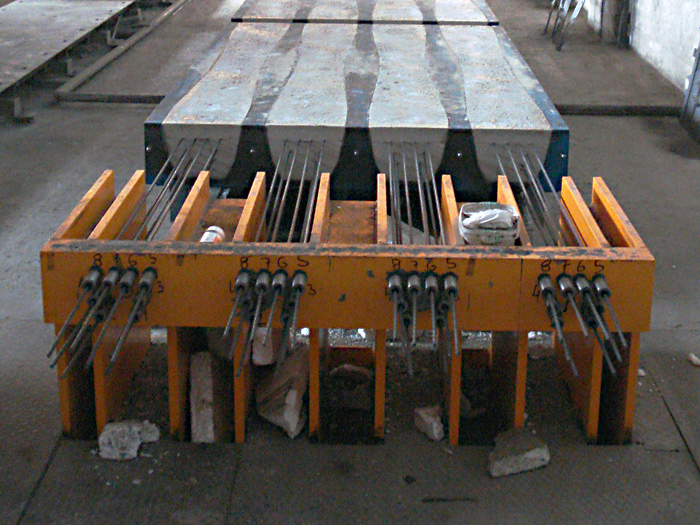

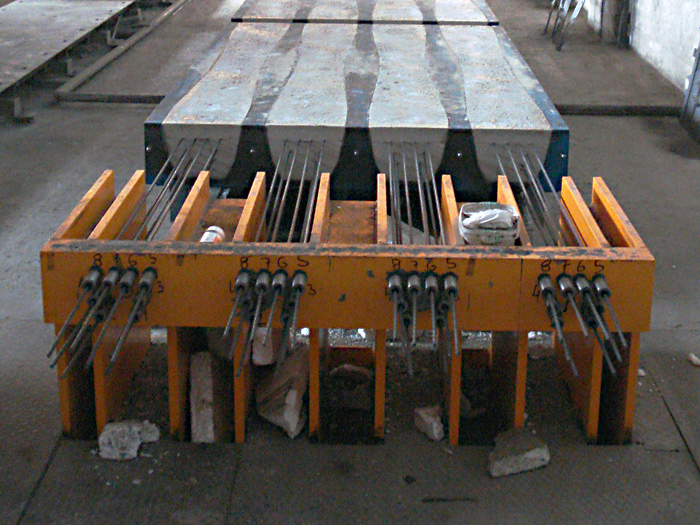

1- pre-tensioning : the steel is tensioned then the concrete will be cast then the steel is cut.

2- post-tensioning : the concrete is cast then the steel is tensioned and cut .

Benefits of prestressed concrete :

Allows longer span , thinner slab and fewer beams .

Lower building height.

Prevent cracking because the cracking is introducing by tension .

There are two main methods to design prestressed concrete members :

1-allowable stress method : in this method we have to check that the actual stresses is equal or less than the allowable stress .

2- load balancing method : in this method we design prestressing steel to carry a percentage of dead load .

There are many things that can be affect on the design such as :

1- type of tendon : bonded or unbonded tendon

2-type of steel : low or normal relaxation

3-the strength of concrete

In the prestressing process the total force doesn't remain constant , there is a drop in force due to losses :

1-short term losses : it is immediate losses occur during prestressed of tendons .

a-elastic shortening of concrete

b-slip at anchorage

c-friction

2-long term losses : it's time dependent losses

a-creep and shrinkage .

b-relaxation of prestressed steel .

This can be happened when the steel is tension until we reach a certain limit then we cut the steel so the force that will applied from steel to the section is compression force .

And we can reduce the stress by introducing moment from the steel by make a eccentricity from the centroid (M=P*e) and the stress will equal (stress=My/I )

The profile of the steel is called tendon and there are many shapes of it :

1- linear profile : we can called this type constant eccentricity .

2- parabolic profile : we can called this type variable eccentricity .

3- linear - parabolic profile

Method of prestressed concrete :

1- pre-tensioning : the steel is tensioned then the concrete will be cast then the steel is cut.

2- post-tensioning : the concrete is cast then the steel is tensioned and cut .

Benefits of prestressed concrete :

Allows longer span , thinner slab and fewer beams .

Lower building height.

Prevent cracking because the cracking is introducing by tension .

There are two main methods to design prestressed concrete members :

1-allowable stress method : in this method we have to check that the actual stresses is equal or less than the allowable stress .

2- load balancing method : in this method we design prestressing steel to carry a percentage of dead load .

There are many things that can be affect on the design such as :

1- type of tendon : bonded or unbonded tendon

2-type of steel : low or normal relaxation

3-the strength of concrete

In the prestressing process the total force doesn't remain constant , there is a drop in force due to losses :

1-short term losses : it is immediate losses occur during prestressed of tendons .

a-elastic shortening of concrete

b-slip at anchorage

c-friction

2-long term losses : it's time dependent losses

a-creep and shrinkage .

b-relaxation of prestressed steel .

No comments:

Post a Comment